The aerospace industry increasingly relies on sophisticated content generation tools to manage vast amounts of technical documentation and research materials. Professional teams utilize AI humanizer platforms to transform complex algorithmic outputs into readable reports. These specialized tools help convert machine-generated data analysis, simulation results, and technical specifications into naturally flowing prose that maintains scientific accuracy while improving accessibility.

The integration of these technologies streamlines documentation workflows and enables research teams to focus on innovation rather than manual content refinement tasks.

Development Phase Cost Analysis

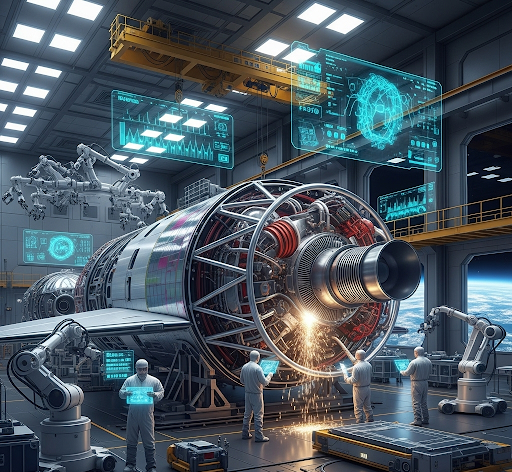

Spacecraft development requires financial investment spanning multiple years of intensive research, design, and testing phases. In fact, the initial stage of conceptualization is already projected to cost hundreds of millions. Engineering teams will be exploring propulsion systems, materials science applications, and mission-specific requirements.

Prototype construction and testing add substantial expenses as manufacturers must create specialized facilities capable of simulating space environments and extreme operating conditions.

R & D expenditures encompass advanced computer modeling software, wind tunnel testing, and materials research that pushes the boundaries of current technology. Teams must invest in cutting-edge simulation systems that can accurately predict spacecraft behavior in zero-gravity environments and extreme temperature variations.

Materials Engineering Investment Requirements

Space-grade materials development represents one of the most expensive aspects of spacecraft construction due to stringent performance requirements and limited supplier availability. Composite materials capable of withstanding radiation exposure, temperature extremes, and micrometeorite impacts require years of research and testing before approval for spaceflight applications. Manufacturing processes for these specialized materials often involve proprietary techniques. In most instances, these techniques are demanding significant capital investment in equipment and facility upgrades.

Quality assurance procedures for space-grade materials add substantial costs as every component must undergo extensive testing to ensure reliability in mission-critical applications.

Certification processes require comprehensive documentation and independent verification that can extend development timelines and increase overall project expenses.

Testing and Validation Expenditures

Comprehensive testing programs consume enormous resources as spacecraft components must demonstrate reliability under conditions that cannot be fully replicated on Earth. Thermal vacuum chambers set the environment in simulating extreme temperatures and pressure conditions that can be encountered in space. On the other hand, vibration testing ensures structural integrity during launch and orbital operations.

Mission simulation software development adds another layer of expense as engineers create detailed virtual environments that model spacecraft behavior throughout entire mission profiles. These complex programs require continuous updates and validation against real-world data to maintain accuracy and usefulness for mission planning purposes.

Launch Infrastructure and Logistics Costs

Ground support systems and launch infrastructure represent major capital expenditures that extend far beyond spacecraft construction costs. Launch pad facilities must accommodate specific vehicle configurations. Aside from that, it must also be able to provide refueling capabilities, payload integration services, and mission control functionality. Not to mention, these specialized installations require regular maintenance and upgrades to support evolving spacecraft designs and mission requirements.

Transportation logistics for spacecraft components add complexity and expense as oversized components often require unique shipping methods and custom handling equipment. International shipping regulations for space-related materials create additional compliance costs and potential delays that must be considered during project planning phases.